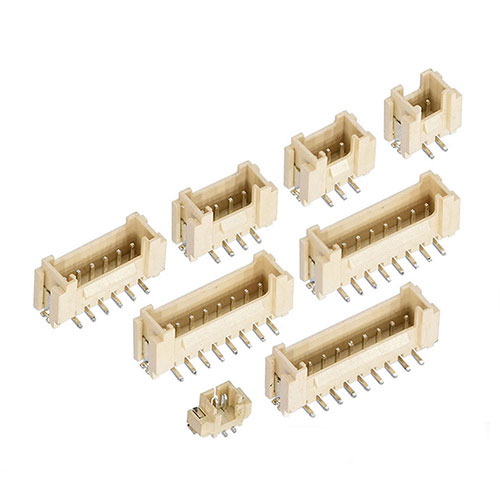

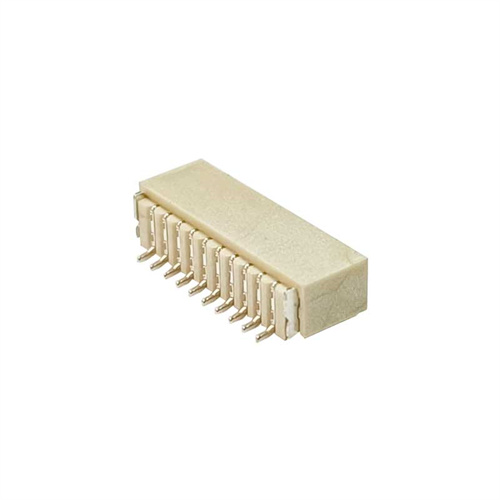

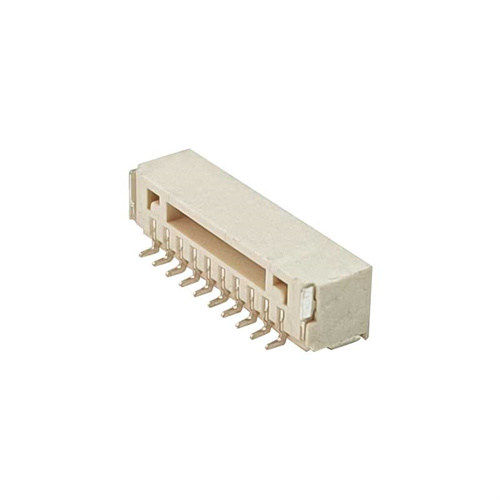

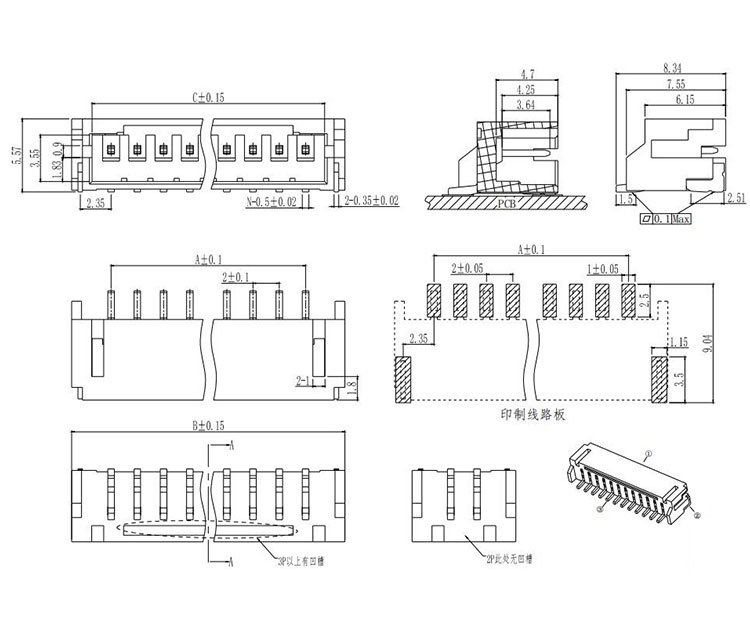

2.0 wafer housing terminal

Wafer housing terminals are an essential component in semiconductor wafer processing equipment

Wafer housing terminals are an essential component in semiconductor wafer processing equipment. They connect semiconductor wafers to process chambers, and enable precision control of temperature, gas flow, and pressure during wafer processing. These terminals are essential in the development of high-performance electronic devices, such as microprocessors, memory chips, and sensors.

Wafer housing terminals are classified into several categories based on their features, materials, and applications. Some of the most common categories of wafer housing terminals are:

1. Material Type:

Wafer housing terminals can be made from different materials such as ceramic, aluminum, stainless steel, and quartz. The choice of material depends on the specific requirements of the wafer processing equipment. For example, quartz terminals are preferred for ultra-high vacuum environments, while ceramic terminals are used in plasma processing.

2. Application Type:

Wafer housing terminals are classified based on their application, such as load lock terminals, process chamber terminals, and transfer chamber terminals. Load lock terminals are used to load and unload wafers from a process chamber, while process chamber terminals are used to connect wafers to the process gases inside the chamber. Transfer chamber terminals are used to transfer wafers between chambers.

3. Connection Type:

Wafer housing terminals can be classified based on the type of connection they use, such as clamp-type, bolt-type, and quick-clamp-type. Clamp-type terminals use a mechanical clamp to secure the wafer and provide a vacuum-tight seal, while bolt-type terminals use bolts to secure the wafer. Quick-clamp-type terminals use a fast-twist locking mechanism to secure the wafer and are used in applications where fast and frequent wafer changes are required.

Overall, wafer housing terminals play a critical role in wafer processing equipment, and their performance and reliability are essential for producing high-quality electronic devices. By choosing the proper terminal types for specific applications, manufacturers can optimize the quality and efficiency of their wafer processing equipment.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Bella

Phone: 15999819066

E-mail: rucoe@rucoe.com

Whatsapp:+86-15999819066

Add: Taoyuan Street, Nanshan, Shenzhen