Metal Chassis Mount DC Power Socket

Metal Chassis Mount DC Power Socket

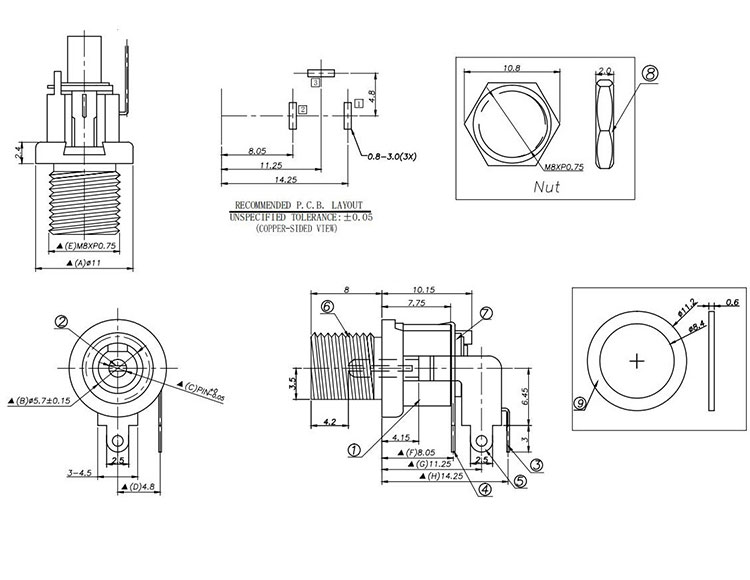

The 2.1mm x 5.5mm size specification is a standard in the industry, ensuring wide compatibility with a vast array of power adapters. The 2.1mm refers to the inner diameter of the socket's center pin, while the 5.5mm is the outer diameter of the socket barrel. This standardization makes it incredibly convenient for manufacturers and users alike, as it allows for easy sourcing of matching power supplies.

One of the standout features of this power socket is its metal construction. The metal panel mount not only offers exceptional mechanical strength but also provides excellent electromagnetic interference (EMI) shielding. In today's tech - saturated environment, where electromagnetic signals can disrupt the operation of sensitive electronics, this shielding is invaluable. It helps protect the connected device from external interference, ensuring stable and reliable performance. Additionally, the metal body can dissipate heat more effectively than its plastic counterparts, reducing the risk of overheating during power transfer.

The Metal Chassis Mount DC Power Socket is a specialized power connection component engineered for secure, long-term installation on equipment chassis (e.g., industrial control panels, medical devices, or automotive dashboards), with its metal construction distinguishing it from plastic alternatives.

Its rugged metal body—typically made of zinc alloy (for cost-effectiveness and impact resistance) or 304 stainless steel (for corrosion resistance)—delivers two critical benefits: first, it withstands physical stress (e.g., repeated plug/unplug cycles, accidental knocks) without cracking, unlike brittle plastic sockets. Second, it provides electromagnetic interference (EMI) shielding, preventing power signal disruption—vital for sensitive electronics like diagnostic tools or precision industrial gear. Many models also feature IP54/IP65 ingress protection, blocking dust and splashes to suit harsh environments (e.g., factory floors or outdoor kiosks).

The “chassis mount” design is equally key: it uses threaded nuts, snap-fit clips, or screws to fasten the socket directly to the equipment’s metal/ABS chassis, creating a stable, vibration-resistant connection. This eliminates the risk of loose wiring or socket displacement—common with panel-mount plastic sockets—ensuring consistent power delivery for heavy-use devices (e.g., industrial printers, automotive infotainment systems).

Ideal for applications demanding reliability and durability, this socket bridges the gap between basic DC sockets and high-performance power components, balancing ease of installation with long-term robustness. It’s a staple in industrial, medical, and automotive sectors where power connection failure could cause downtime or safety risks.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Bella

Phone: 15999819066

E-mail: rucoe@rucoe.com

Whatsapp:+86-15999819066

Add: Taoyuan Street, Nanshan, Shenzhen