DC Connector Jack

DC Jack Socket (Solder) 2.0mm Pin

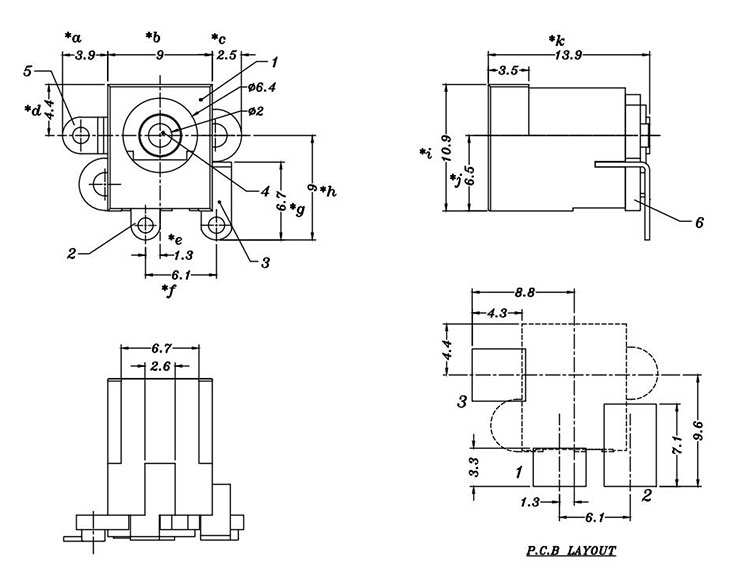

The DC power jack vertical THT is a type of power connector designed to be mounted on a printed circuit board (PCB) using the through - hole technology. As the name implies, the "vertical" aspect refers to the orientation of the jack on the PCB, where it stands upright perpendicular to the board's surface. The through - hole technology involves inserting the pins of the jack through holes drilled in the PCB and then soldering them on the opposite side. This method provides a robust mechanical and electrical connection, making it suitable for a wide range of applications.

Physical Structure

The DC power jack vertical THT typically has a cylindrical shape with an outer barrel and an inner center pin. The outer barrel serves as the negative terminal, while the center pin is the positive terminal. The jack is often made of durable materials such as plastic for the body and metal (usually brass or copper) for the contacts. The metal contacts are sometimes plated with materials like gold or silver to enhance conductivity, reduce oxidation, and improve the overall lifespan of the connector.

Electrical Characteristics

These power jacks are designed to handle specific DC voltage and current ratings. Common voltage ratings can range from a few volts up to 24 volts or more, depending on the model, while the current - handling capacity can vary from a few hundred milliamperes to several amperes. They are engineered to have low contact resistance, ensuring efficient power transfer with minimal power losses and heat generation.

Mounting and Installation

The through - hole mounting process of the vertical THT DC power jack offers several advantages. Once inserted through the PCB holes, the pins are soldered, creating a strong bond that can withstand mechanical stress, vibrations, and temperature variations. This makes it ideal for applications where the PCB may be subject to movement or where a long - lasting connection is required. Additionally, the vertical orientation allows for easy access to the power jack from the top side of the PCB, facilitating the connection of power cable.

Benefits

Durability and Reliability

The through - hole soldering process provides a secure and long - lasting connection. The mechanical strength of the soldered joints ensures that the power jack remains firmly attached to the PCB, even in challenging environments. This reliability is crucial for devices that are constantly in use or operate in conditions with vibrations, such as automotive electronics or industrial equipment.

Compatibility

DC power jack vertical THTs are available in a variety of standard sizes and configurations, making them highly compatible with a wide range of power adapters and electronic devices. This standardization simplifies the design and manufacturing process for engineers, as they can easily source and integrate these jacks into their PCB designs.

Ease of Assembly and Repair

For manufacturers, the through - hole technology is relatively straightforward and can be easily automated. This reduces production time and costs. In terms of repair, if the power jack fails, it can be relatively easily desoldered and replaced, making maintenance more convenient.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Bella

Phone: 15999819066

E-mail: rucoe@rucoe.com

Whatsapp:+86-15999819066

Add: Taoyuan Street, Nanshan, Shenzhen