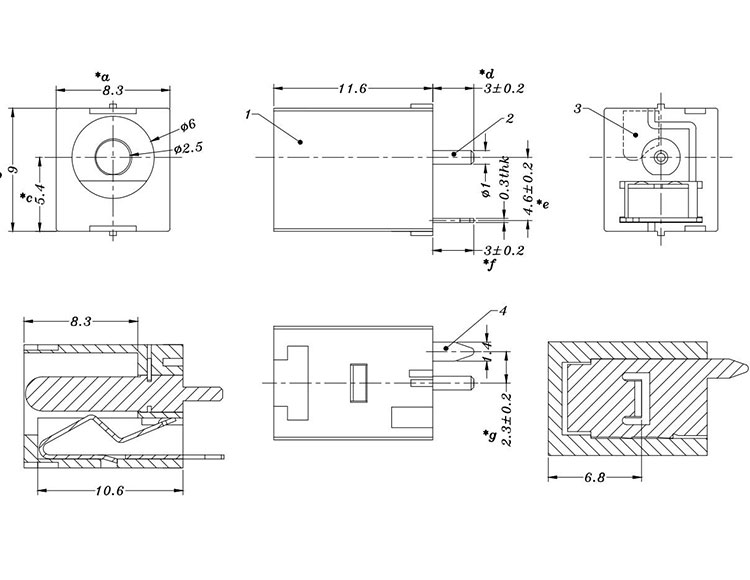

DC Power Supply jack

DC Jack Socket (Solder) 2.0mm Pin

The vertical PCB mount DC Power Supply jack is a compact, board-integrated power connection component engineered to mount perpendicularly to printed circuit boards (PCBs)—a design that sets it apart from horizontal PCB jacks and chassis-mount alternatives, making it ideal for space-constrained devices.

Its core structure balances functionality and efficiency: it uses either through-hole (THD) or surface-mount (SMT) terminals to secure directly to the PCB, ensuring stable mechanical attachment and reliable electrical conductivity. Contacts are typically made of brass or phosphor bronze (for low resistance and wear resistance), while the housing often uses heat-resistant plastics (PBT or ABS) or reinforced metal (for EMI shielding in sensitive devices). The vertical orientation means the jack’s plug-in port faces upward (or outward, depending on PCB layout), minimizing horizontal space usage—critical for slim devices like portable chargers, IoT sensors, or small industrial control modules.

Key benefits include:

1) Space efficiency: Reduces PCB footprint by leveraging vertical height, a must for compact electronics.

2) Automated assembly compatibility: SMT/THD designs integrate seamlessly with PCB assembly lines, cutting production time.

3) Vibration resistance: Direct PCB mounting eliminates loose connections from external stress, suitable for devices like automotive infotainment systems or portable medical tools.

4) Polarity protection (in premium models): Prevents damage from reverse plug insertion, a common issue in consumer electronics.

The through - hole mounting technique used for the 5A DC Power Jack Vert PCB Mount ensures a secure and reliable attachment to the PCB. The pins of the jack are inserted through pre - drilled holes on the board, and then soldered on the other side. This soldering process creates a strong mechanical and electrical bond, allowing the power jack to withstand vibrations, shocks, and other mechanical stresses that may occur during the operation of the device. The vertical positioning also makes it easier to route cables and manage the overall layout of the PCB, contributing to a more organized and efficient design.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Bella

Phone: 15999819066

E-mail: rucoe@rucoe.com

Whatsapp:+86-15999819066

Add: Taoyuan Street, Nanshan, Shenzhen