Metal Panel Mount DC Jack

The 2.1MM Metal Panel Mount DC Jack is a specialized power connection component tailored for secure installation on equipment panels

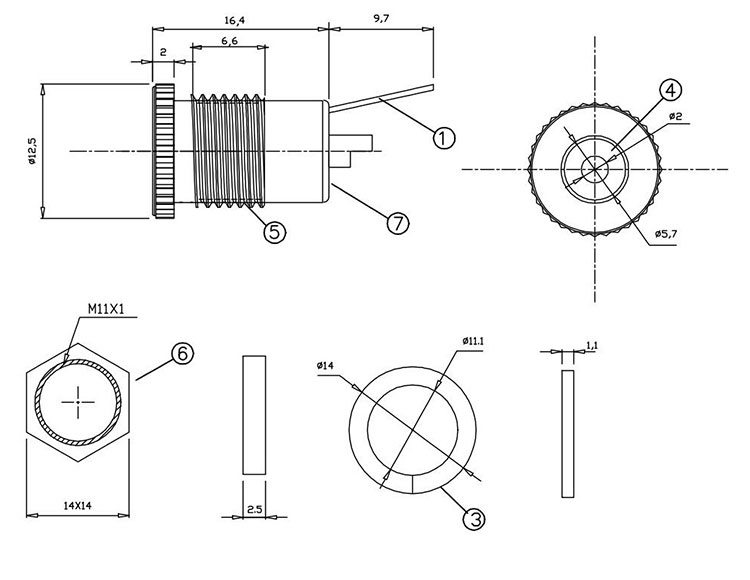

The 2.1MM Metal Panel Mount DC Jack is a specialized power connection component tailored for secure installation on equipment panels, with a 2.1mm inner pin diameter (matching the industry-standard 2.1x5.5mm DC plug) and rugged metal construction—addressing the need for compatibility, durability, and stable power delivery in consumer, industrial, and medical devices.

Its core design centers on two critical traits: the 2.1mm contact 规格 and metal panel-mount structure. The 2.1mm inner pin (typically brass or phosphor bronze for low resistance and wear) ensures universal compatibility with the most common DC plugs used in small electronics, from routers to industrial sensors. The metal housing—usually zinc alloy (cost-effective, impact-resistant) or 304 stainless steel (corrosion-resistant for harsh environments)—forms a robust outer layer, unlike plastic jacks that crack under repeated use or vibration. For installation, it uses threaded nuts or snap-fit clips to fasten directly to panels (1–5mm thickness, typical for control boxes or device enclosures), creating a tight, vibration-proof seal that prevents loose connections.

Designed for panel mounting, this 2.1mm Metal Panel Mount DC Barrel Power Jack has a threaded outer barrel that allows it to be securely fastened through a pre - drilled hole in the panel of an electronic device or enclosure. The threaded design, along with a nut and washer, ensures a stable and reliable installation. Inside the metal body, the jack contains the essential electrical contacts. These contacts are usually made of highly conductive metals, like copper, and may be gold - or silver - plated to reduce contact resistance, prevent oxidation, and enhance electrical conductivity.

The 2.1mm metal panel mount DC power jack is engineered to handle specific DC voltage and current ratings. Common voltage ratings range from 5V to 24V, and it can typically handle currents from a few hundred milliamperes to several amperes, depending on the specific model and design. The low contact resistance of the internal contacts ensures efficient power transfer, minimizing power losses and heat generation during operation. This is crucial for maintaining the stability and performance of the connected electronic device, as excessive heat can lead to component failure and reduced lifespan.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Bella

Phone: 15999819066

E-mail: rucoe@rucoe.com

Whatsapp:+86-15999819066

Add: Taoyuan Street, Nanshan, Shenzhen